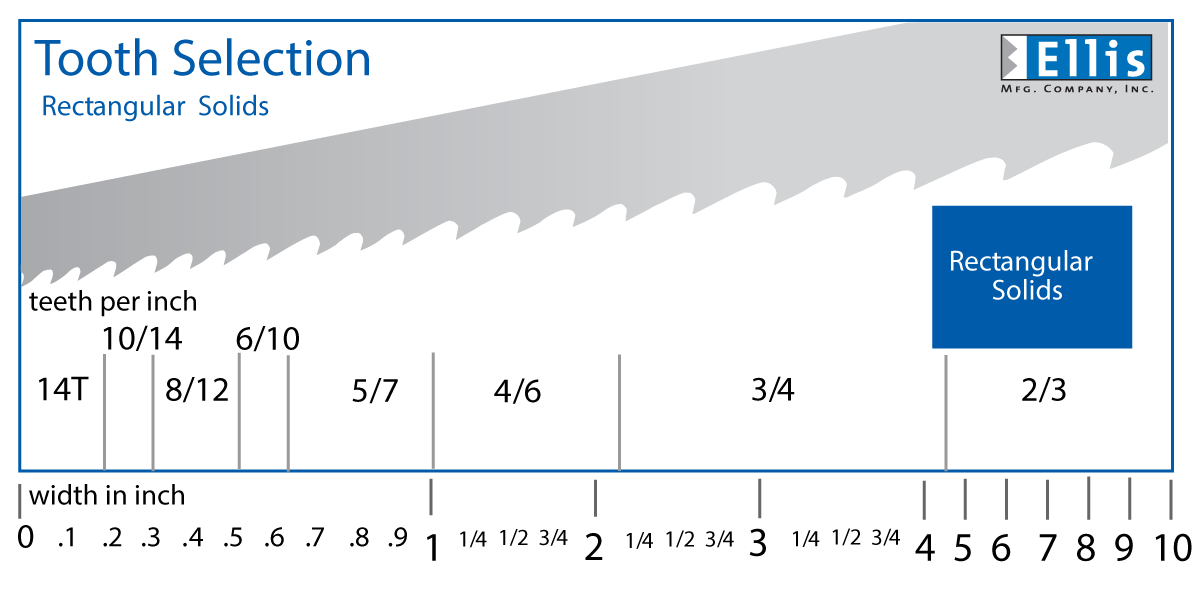

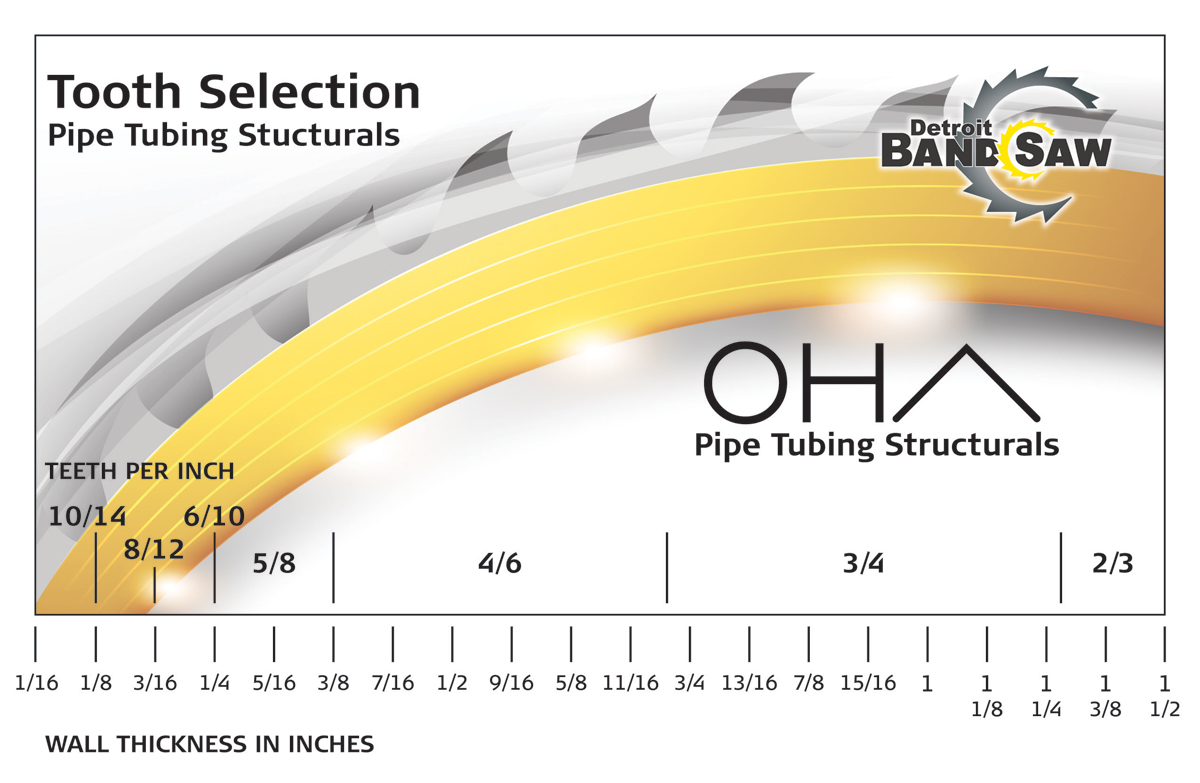

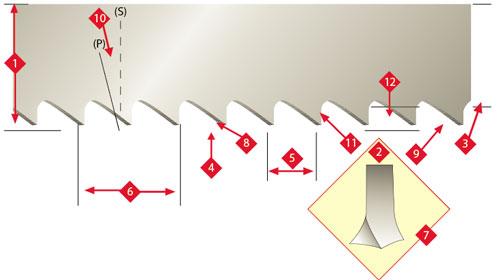

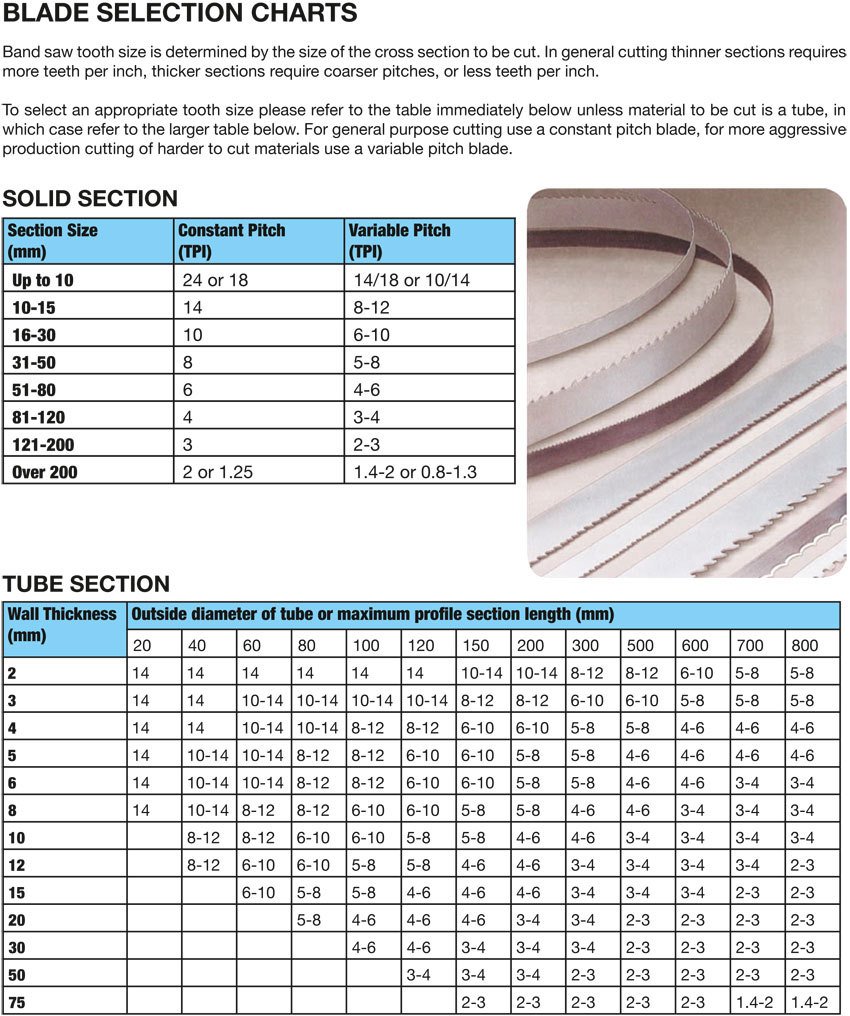

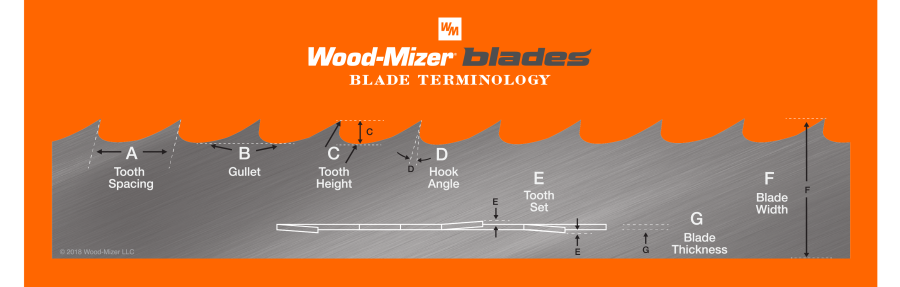

Tooth selection guide teeth per inch band saw tooth size teeth per inch is determined by the size and type of material to be cut and the desired finish.

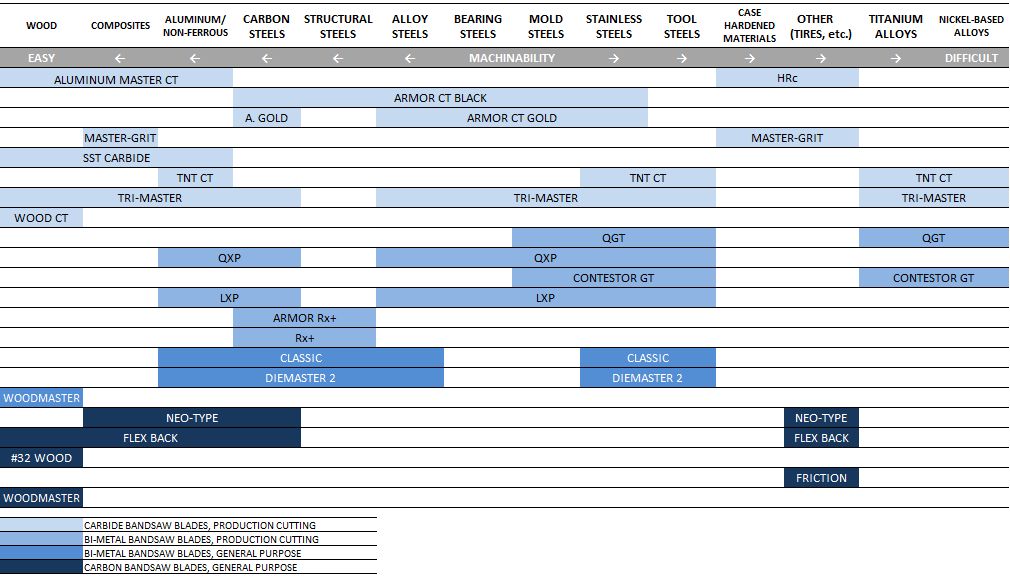

Metal band saw blade tooth selection.

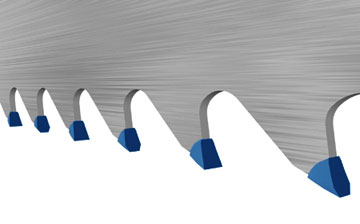

Bandsaw blades used for cutting metal have bent teeth.

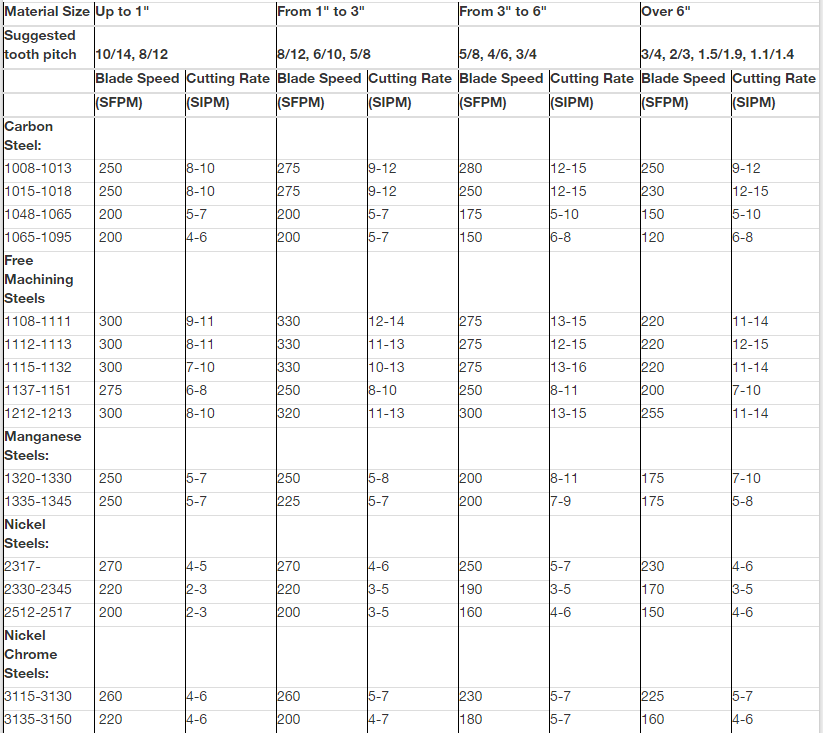

Using this chart find the colored chart for the type of material you wish to cut.

Select a tooth per inch tpi based on the charts below.

Tooth selection tpi band saw tooth size is determined by the size and type of material to be cut and the desired finish.

Band saw blade break in procedure.

Flap disc aluminium oxide zirconia oxide mops wheel flap wheel on.

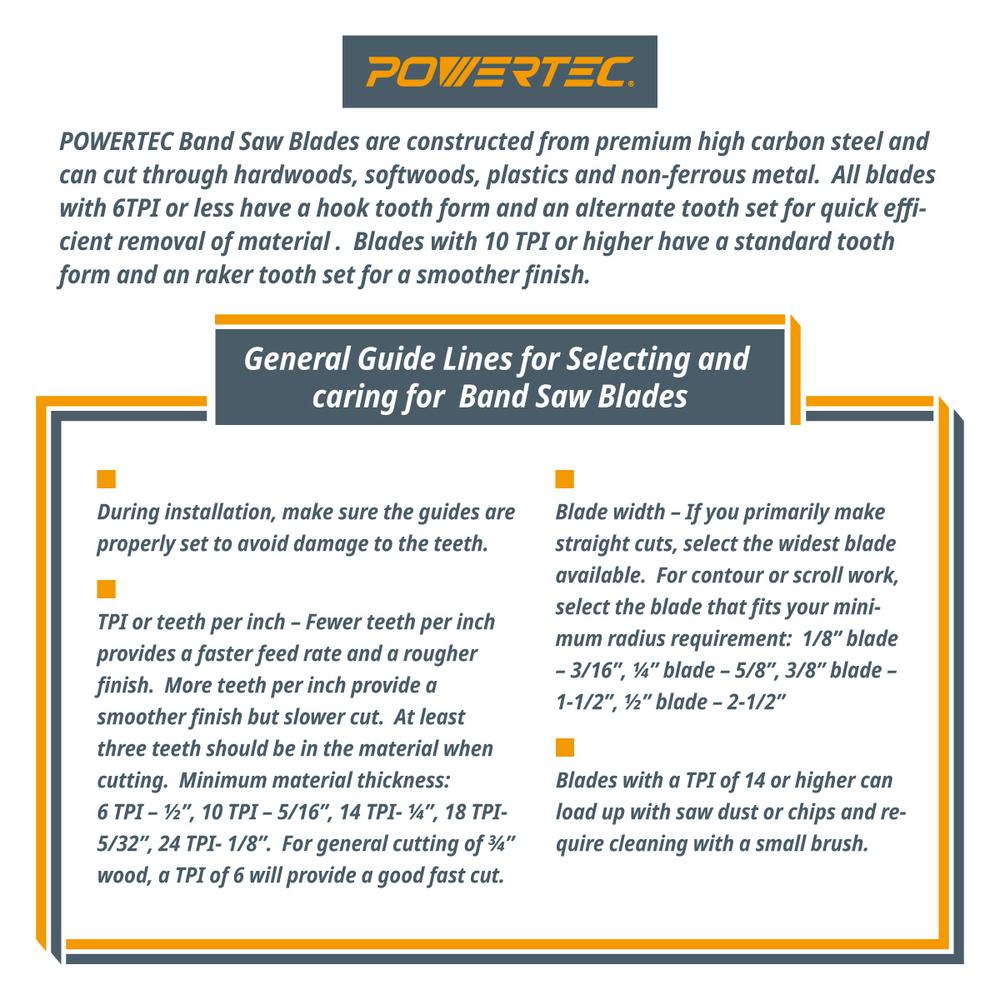

Improper tooth selection use a finer pitch.

Band saw blade problems and solutions.

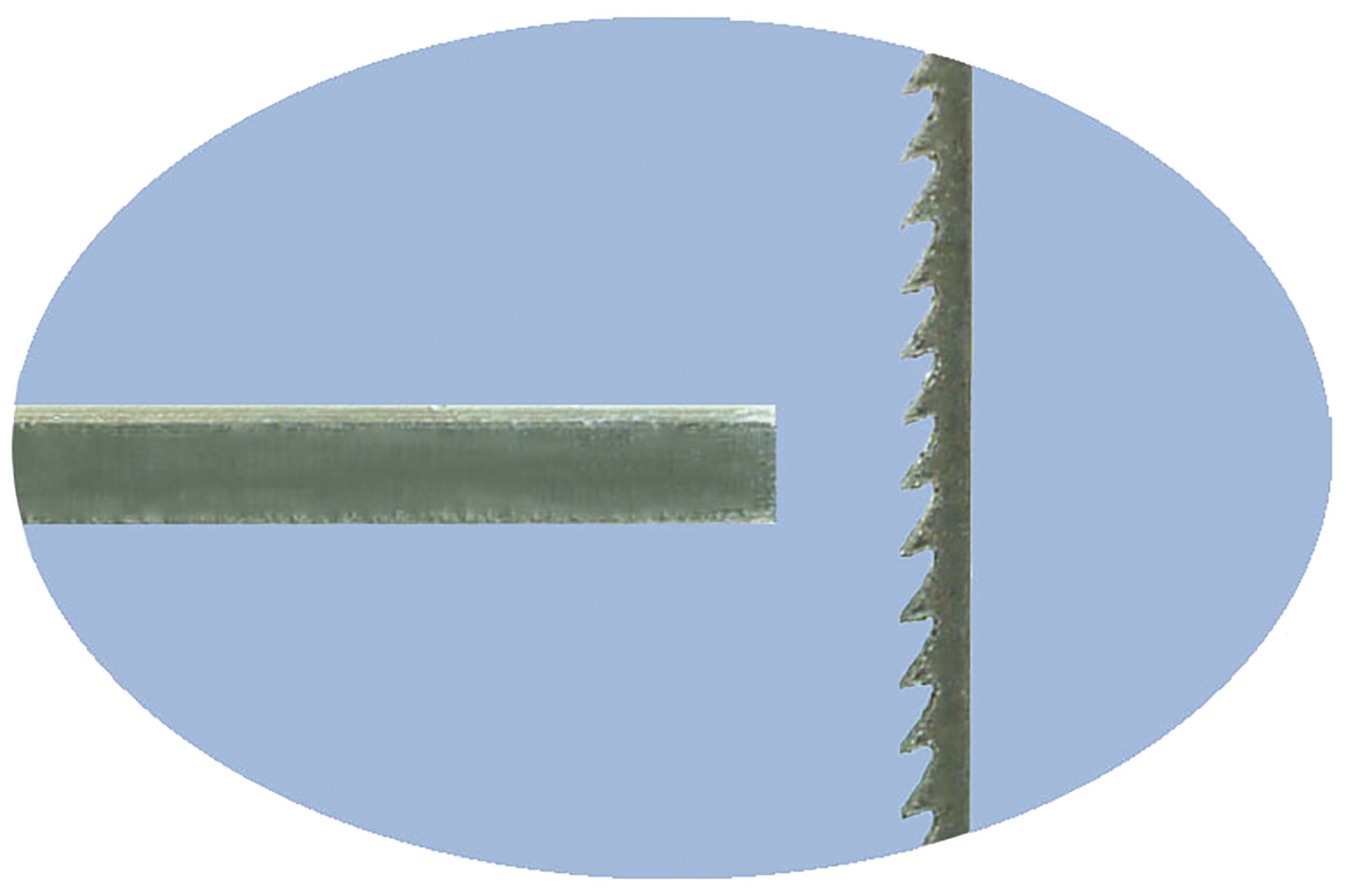

Be sure teeth are pointing in proper direction.

Follow across to the chart for.

Resin metal cloth tape roll.

Aluminium oxide fibre disc.

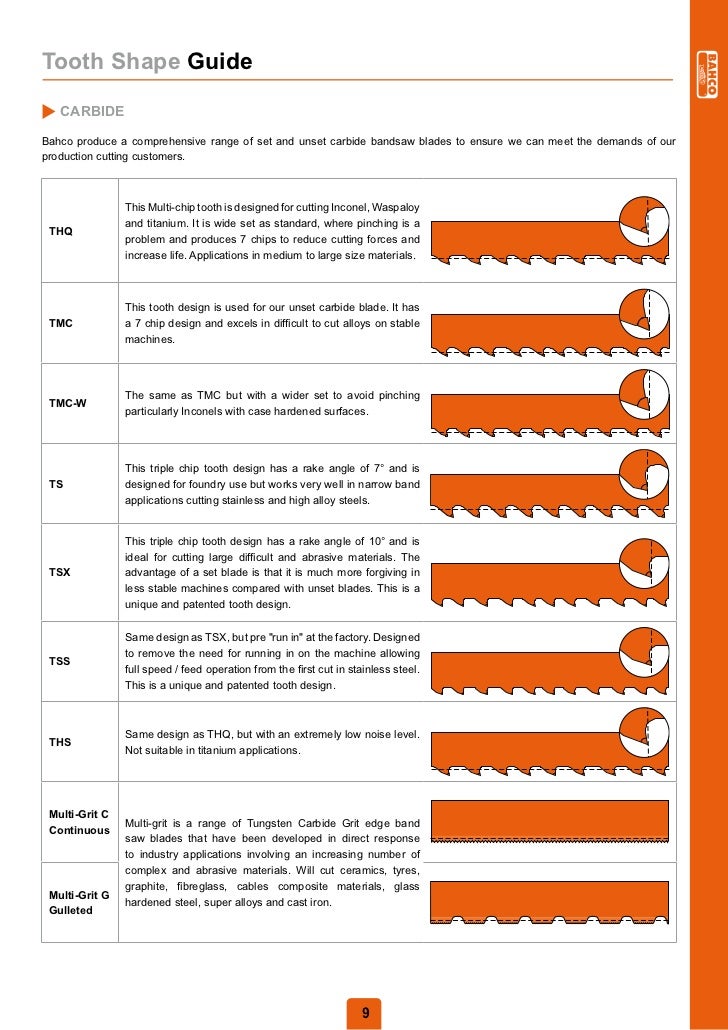

How to choose a metal cutting band saw blade rake material and teeth.

I have seen many band saws and other kinds of saws ruined because the person attempted to cut through a certain kind of material with the wrong kind of blade.

Teeth are running the wrong direction.

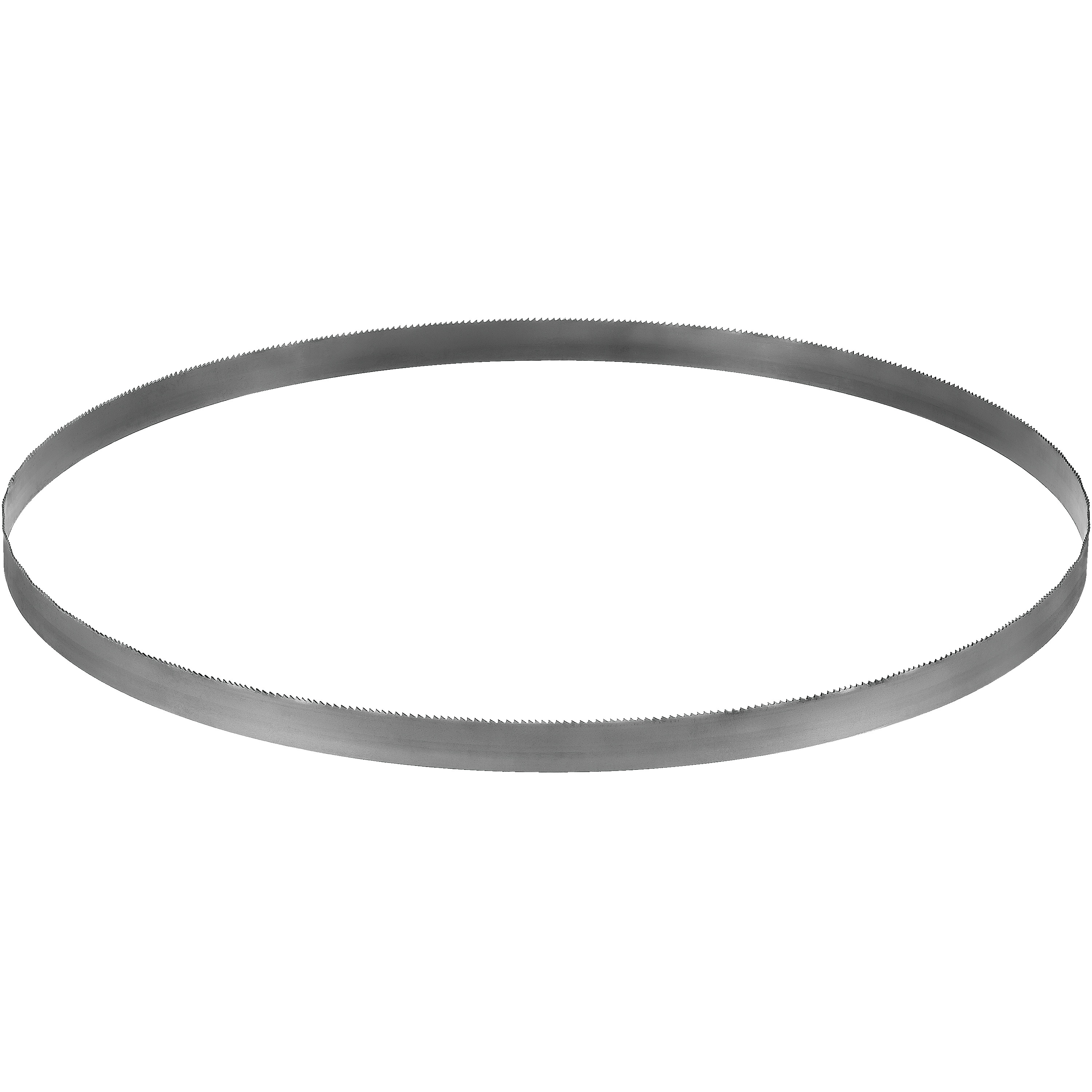

Custom welded band saw blade that are manufactured with our precision ground rugged tooth our metal cutting band saw blades are an excellent choice for cutting a variety of all shapes and sizes of steel.

Resin metal cloth belt.

You want to be very careful with your blade selection when cutting metal.

Low alloy steel pata.

Run the normal surface feet per minute sfm.

The progressive positive rake tooth pattern is designed to reduce noise vibration and chatter giving you a quicker sawing operation and extending blade life resulting in a lower cost.

In stock and ready to ship.

The bend in the teeth creates a cut slightly wider than the thickness of the blade which is important to prevent the blade from getting stuck from being pinched by the metal.

Tpi for maximum cutting efficiency and lowest cost per cut it is important to select a blade with the right number of teeth per inch tpi for the material you are cutting.

Find material dimensions on bottom of chart and move up for appropriate teeth per inch.

Abrasive cutting grinding discs.

The proper break in of a bi metal blade assures longer blade life faster cuts for a longer period of time and consistent performance.

Band speed feed lubrication and blade design as shown in the following sections.

Incorrect saw guide insert size for the band allowing them to strike teeth 2.

To avoid stripping teeth always have a minimum of three teeth in the work.

Move up to the correct material size next to the chart.