Easy maintenance longer pump life liquid ring vacuum pumps are robust in construction and have only one moving part the rotor which is mounted on a shaft supported by a set of bearings designed for a long service life of continuous operation.

Liquid ring vacuum pump gif.

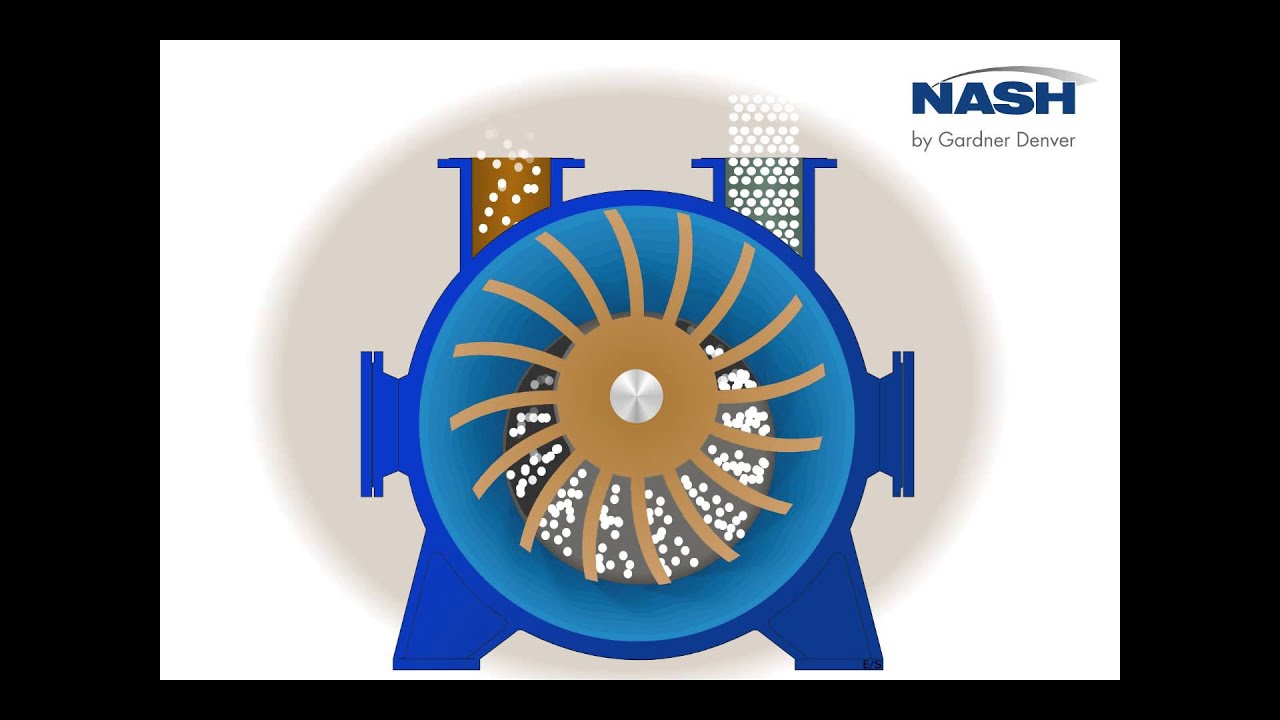

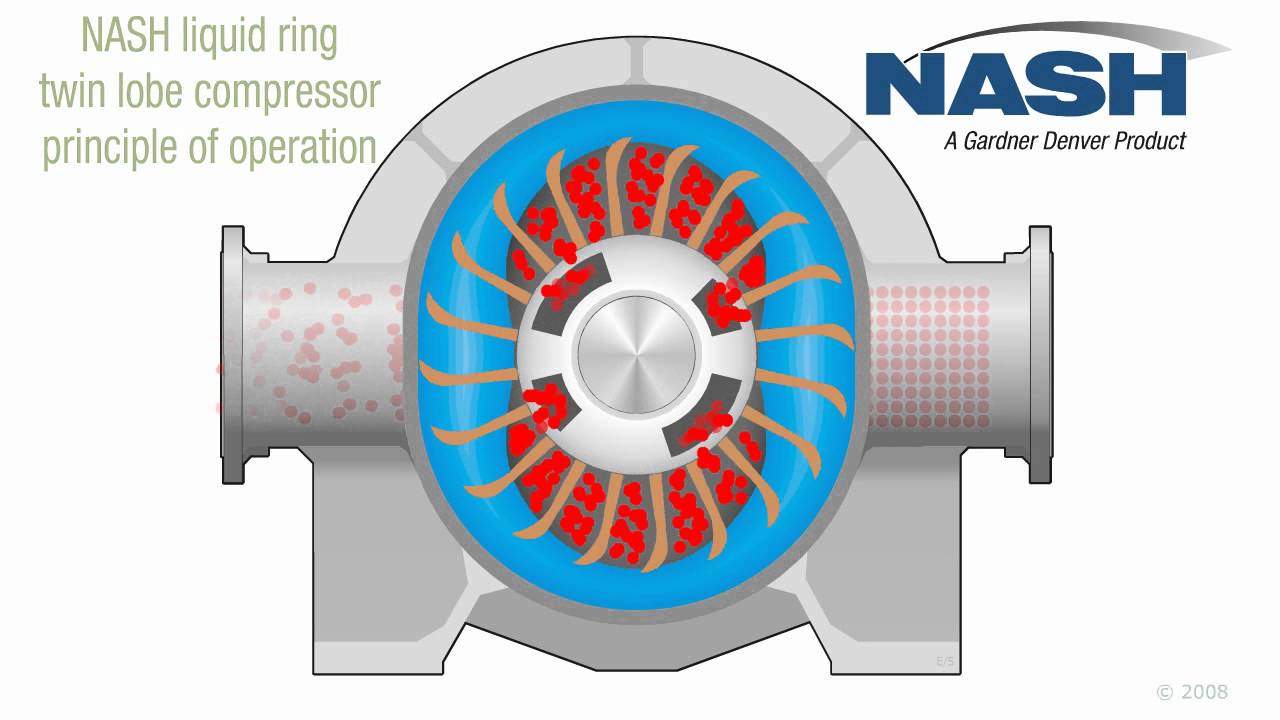

As the shaft turns a liquid ring is created by the centrifugal force generated by the rotating impeller.

Similar to other pumps a liquid ring vacuum pump lrvp has a bladed impeller attached to a center hub.

The fluid at the pump suction port flange has a low pressure value whereas after passing through the various pumps impellers stages the fluid is.

Typical centrifugal pumps increase the operating pressure of pumped fluid.

This benefits the user with less wear and simpler affordable maintenance.

This force holds the liquid ring against the.

Environmental pumps do not require an oil change filter oil pans.

Recommended approach to liquid ring vacuum pump maintenance.

Behavior traits that seem out of the ordinary could easily be indicative of developing troubles inside.

They are typically used as a vacuum pump but can also be used as a gas compressor the function of a liquid ring pump is similar to a rotary vane pump with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression chamber seal.

Find out how the nash liquid ring vacuum pump w.

To produce vacuum in a two stage liquid ring vacuum pump a multi blade impeller on a shaft is positioned eccentrically in a cylindrical housing that is partially filled with sealing liquid.

For more than 110 years nash liquid ring technology has provided reliable solutions for process applications.

A liquid ring pump is a rotating positive displacement pump.